Starting model: Tiggo 8 PLUS Kunpeng e+

Before, we have talked about the hybrid systems of three domestic OEMs, namely "Great Wall Lemon Hybrid DHT System", "Geely Lei Shenqing Hi·X Hybrid System" and "BYD DM Hybrid System". Today, let’s talk about "Chery Kunpeng DHT Hybrid System" and see what kind of surprises Chery Automobile with "dead-knock technology" can bring us.

As one of the four modules under the strategy of "Chery 4.0 era", "Chery Kunpeng DHT hybrid system" is of great significance to Chery Automobile, so we should first analyze the structure and principle of this hybrid system.

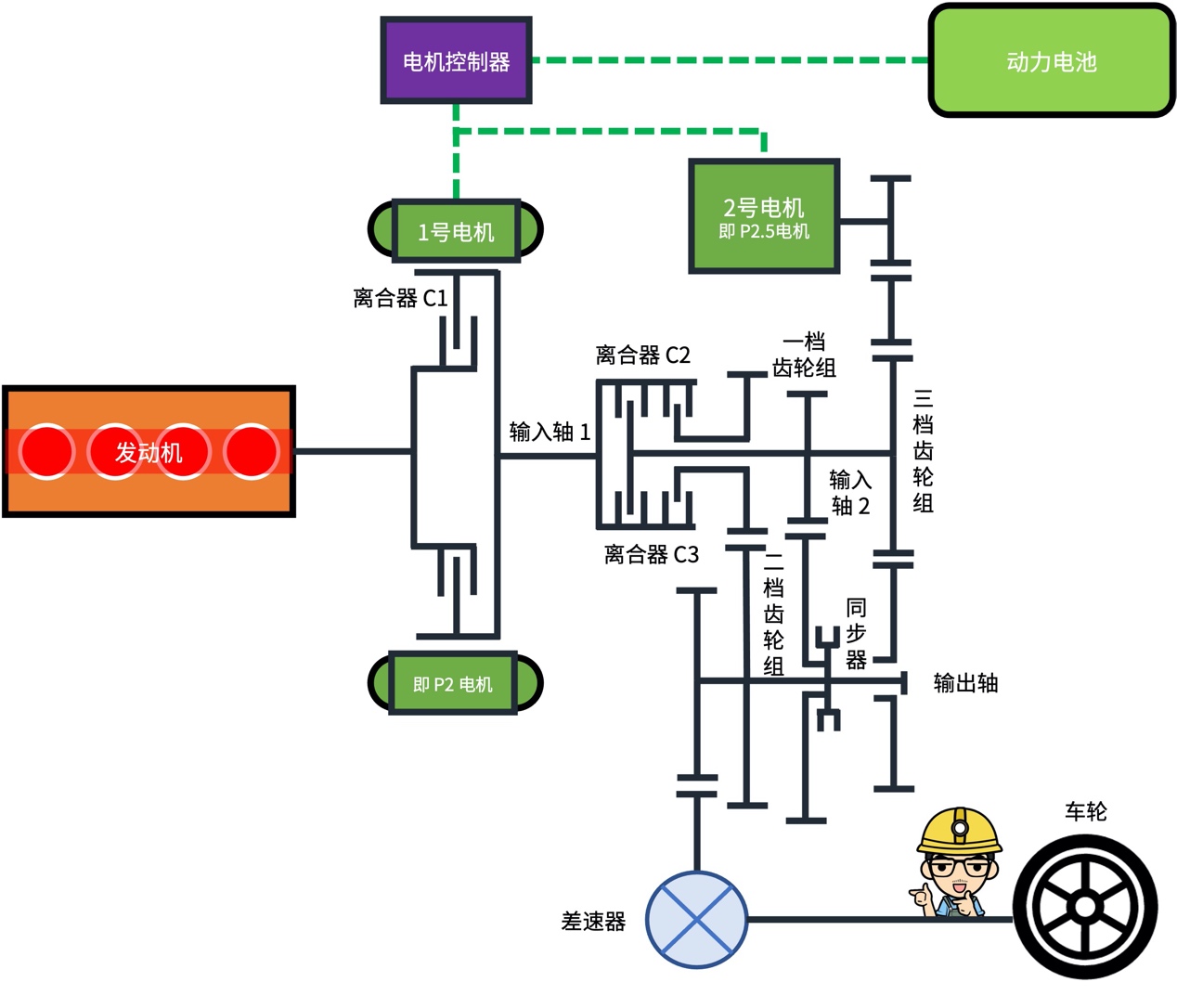

Schematic diagram of Chery Kunpeng DHT hybrid system

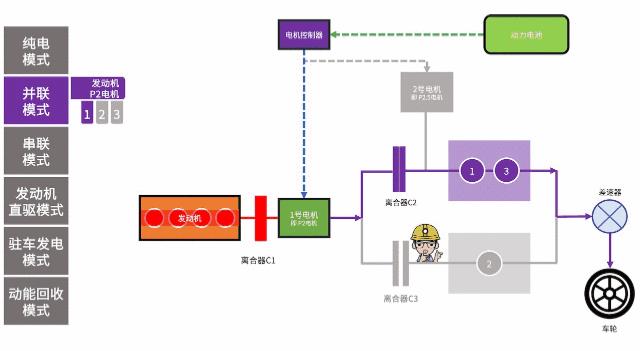

First of all, to sum up the "Chery Kunpeng DHT Hybrid System" in one sentence is:A set of classic structure with "double clutch transmission"(Simplify "gear" to third gear)And the "P2 motor" and "P2.5 motor" are deeply integrated.

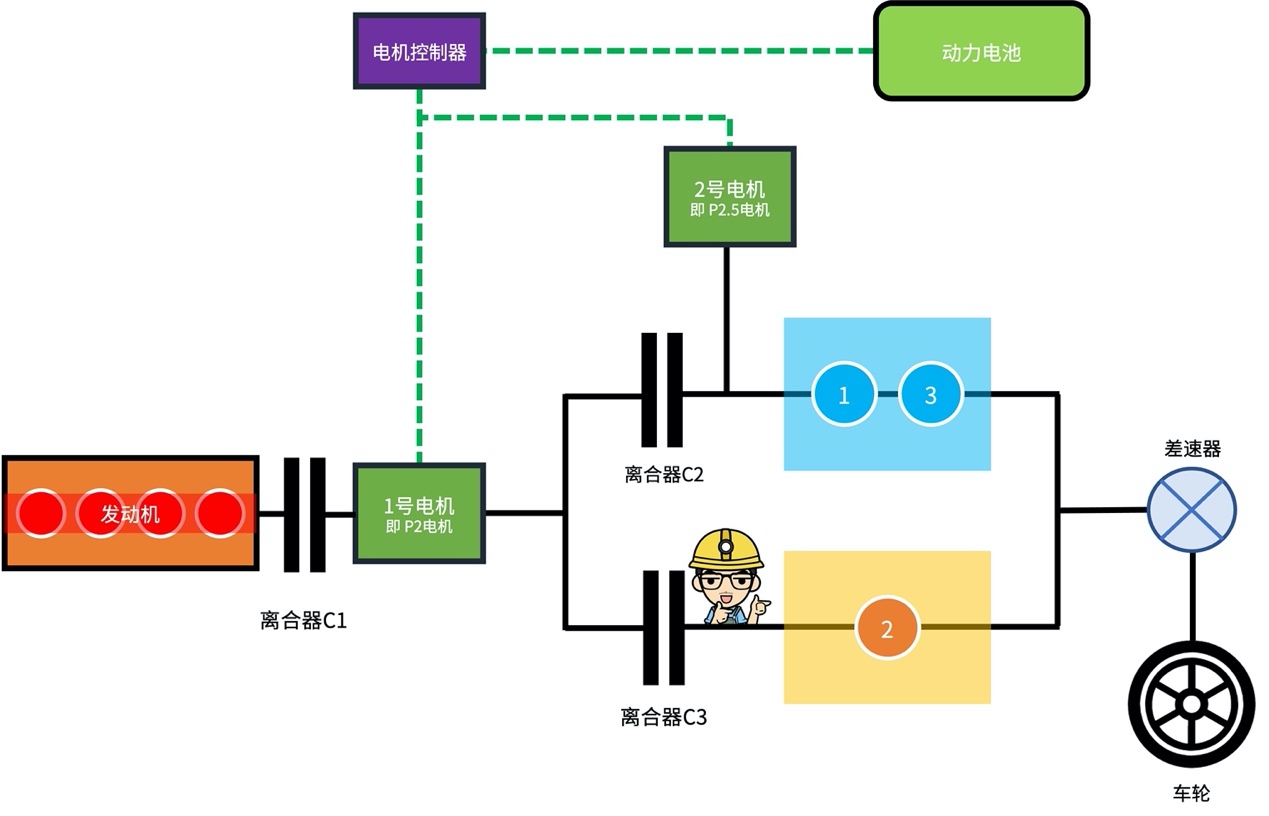

Chery Kunpeng DHT mass production exhibition map

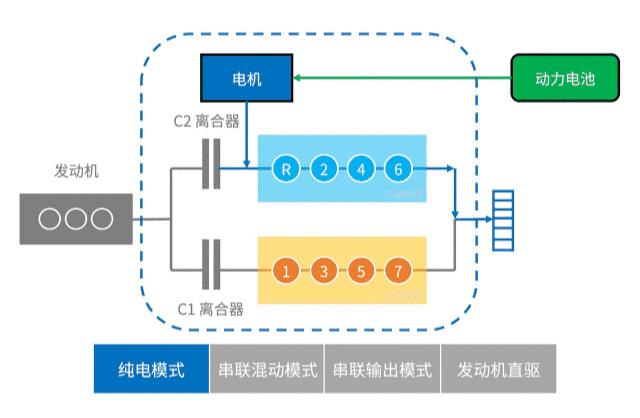

Judging from the pictures released by the government, the internal structure connection logic of the core component-"DHT" is roughly as follows:

1. The "engine" is coaxially connected with the "P2 motor" and can be disconnected through the "clutch";

2. The "P2.5 motors" are arranged in parallel and transmit power through the "reduction gears";

3. The "motor controller" is integrated above the powertrain;

4. Adopt "electronic pump" and "mechanical pump" to provide pressure and lubrication for the whole system.

Explosion diagram of Chery Kunpeng DHT structure

Due to the lack of official information, we found a patent (patent number: CN110667366A) applied by Chery Automobile in this field, and redrawn the "Chery Kunpeng DHT Hybrid System" based on this patent and the explosion diagram released by the government.

According to the patent of Chery Automobile, the sketch map of the structure of Chery Kunpeng DHT hybrid system is redrawn (for reference only).

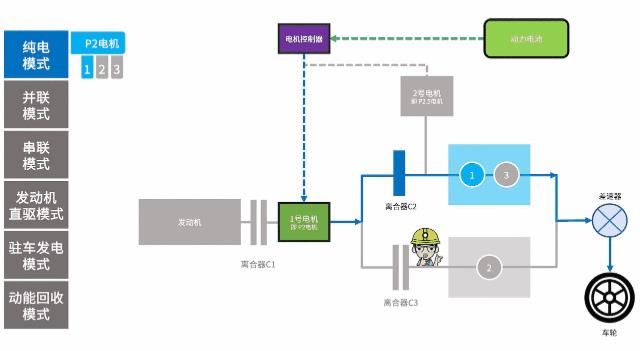

In addition to obtaining the connection logic from the explosion diagram, the patent also defines the positions of three gears and the control logic of three groups of clutches:

1. "Clutch C1" controls whether the "engine" is involved in the whole power system;

2. "Clutch C2" can control whether the power passes through the "speed change gear" of 1st and 3rd gears;

3. "Clutch C3" mainly controls whether the power passes through the "speed change gear" of 2nd gear.

Structural diagram of Chery Kunpeng DHT hybrid system (simplified version)

In addition, the whole set of "transmission" shifts gears through "synchronizer", which is basically the same as the traditional "powershift" in structure and principle. Of course, when you see this, everyone must look puzzled. Don’t be afraid. I will explain the working conditions of each component in different modes in the next working principle.

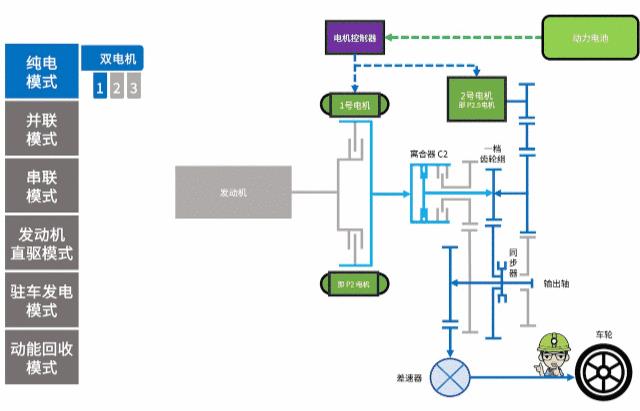

According to Chery Automobile, the working mode of "Chery Kunpeng DHT Hybrid System" is summarized as "3 gears, 9 modes and 11 speeds", that is, 3 adjustable physical gears, 9 working modes and 11 speed ratios.

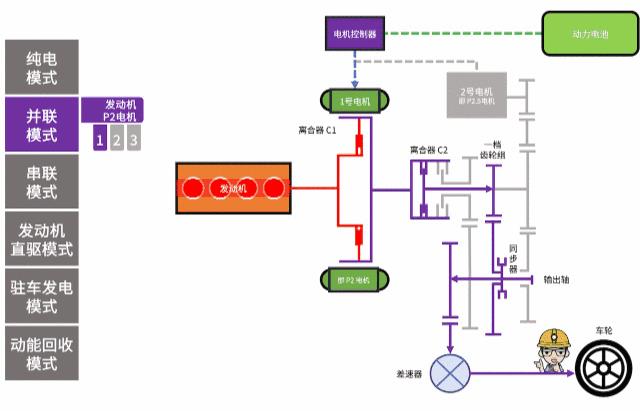

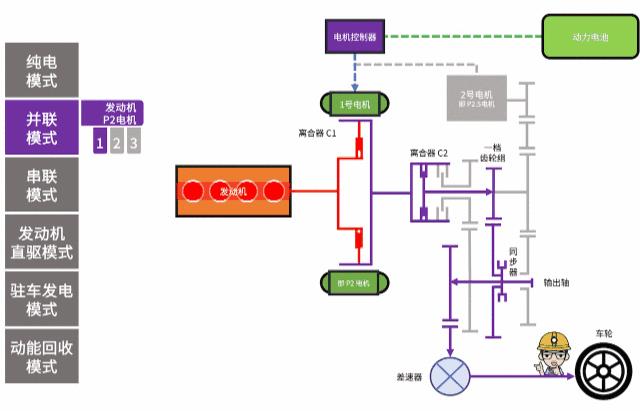

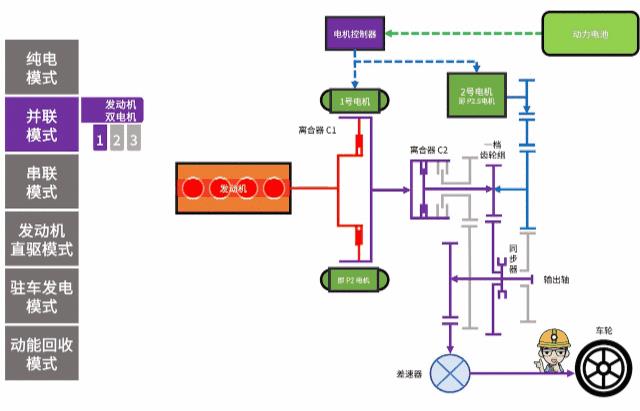

Schematic diagram of working principle of Chery Kunpeng DHT hybrid system (detailed version, for reference only)

In order to keep the unified description of the working modes in this series, I have summarized the official 9 driving modes and 11 speed ratios into 6 working modes, namely pure electric mode, parallel mode, series mode, engine direct drive mode, parking power generation mode and kinetic energy recovery mode, and the above animation briefly shows 24 power transmission paths that can be realized by Chery Kunpeng DHT Hybrid System. Next, we will analyze the patterns one by one.

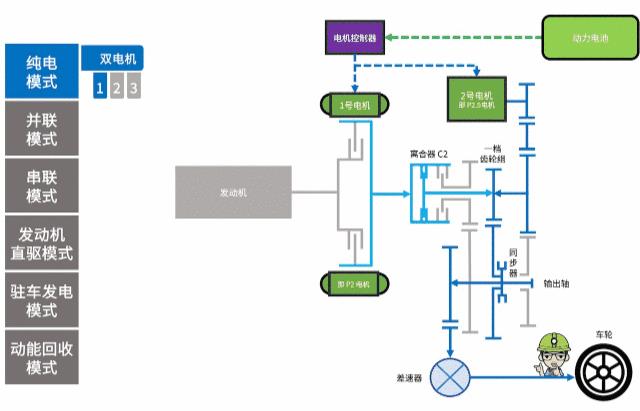

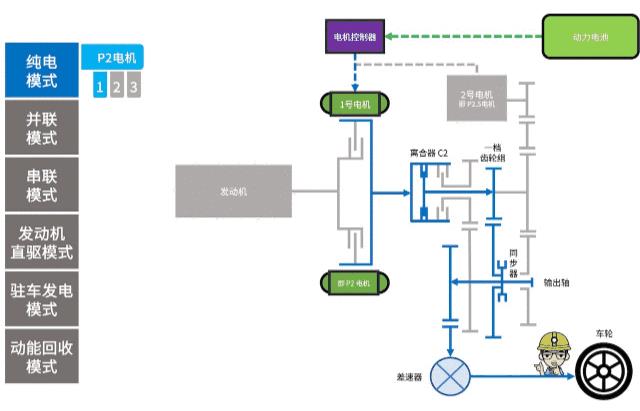

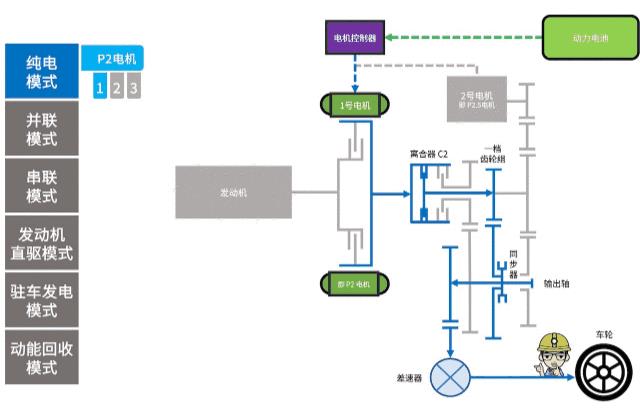

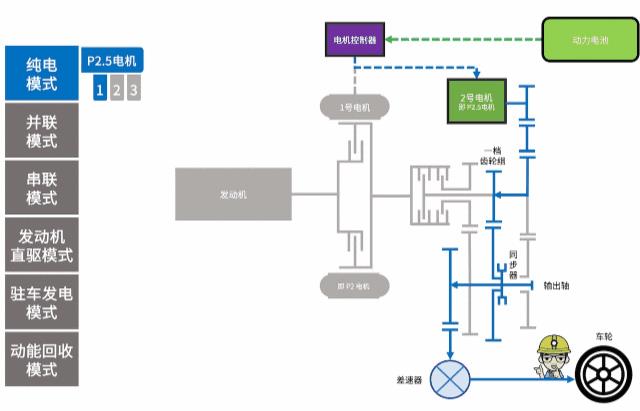

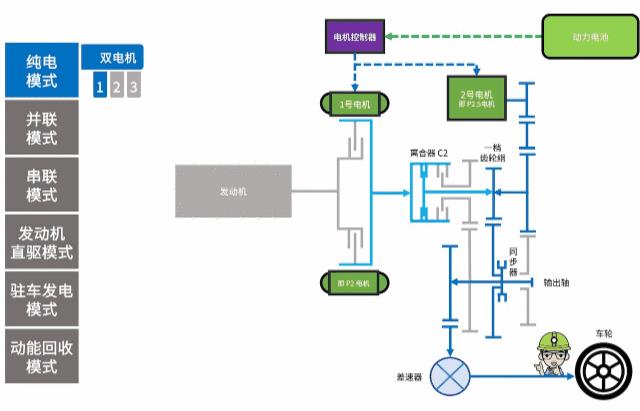

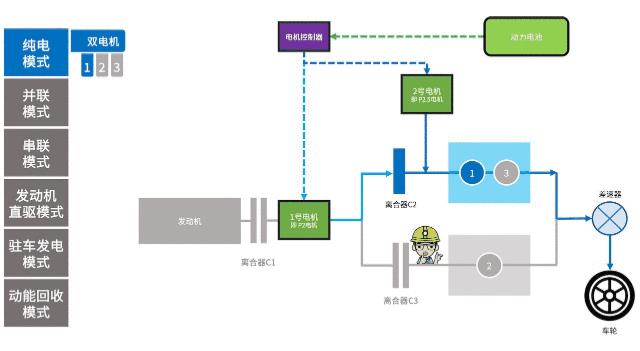

Overview of three pure electric drive modes (detailed version, for reference only)

Because the "Chery Kunpeng DHT Hybrid System" consists of two "motors" that can be used for driving, its pure electric mode is divided into"pure electric drive mode of P2 motor", "pure electric drive mode of P2.5 motor" and "pure electric drive mode of double motors".

"Pure electric drive mode of P2 motor"When cruising at low speed with low power requirements, only the P2 motor (No.1 motor in the figure) is needed for driving, so the clutch C1 is decoupled and the engine does not participate in the work. In addition, the first, second and third gears can be switched through the coupling control of clutch C2 and clutch C3 to meet the corresponding power demand;

"P2.5 pure electric drive mode of motor":When the power demand increases, the "P2.5 motor" ("No.2 motor" in the figure) with slightly higher power will output power through the second "input shaft", and the first and third gears can still be changed at this time;

"Double-motor pure electric drive mode"When the power demand is further increased, two "motors" work in parallel, and four combinations of 1st gear, 3rd gear, 1st+2nd gear and 2nd+3rd gear are realized by matching two sets of "clutches".

Overview of three pure electric drive modes (simplified version, for reference only)

Three pure electric drive modes are suitable for low-speed acceleration, high-speed cruise, frequent start-stop and other working conditions, and meet the comprehensive needs of economy and comfort. In addition, the theoretical maximum power can also exceed 120kW(55kW+70kW) under the "dual-motor pure electric drive mode", which can also bring good power effect.

Overview of two parallel driving modes (detailed version, for reference only)

Similar to the logic of pure electric mode, parallel mode also has the participation of "P2 motor""Single motor parallel drive mode"And two "motors" working at the same time."Double-motor parallel drive mode". The difference is that considering the transmission power efficiency, there is no single parallel combination of "P2.5 motor".

"Single motor parallel drive mode":Since they are connected in parallel, the "engine" must participate in the power output. Therefore, the "clutch C1" is coupled, and the "P2 motor" and the "engine" work together on the first "output shaft". At this time, the "clutch C2" and the "clutch C3" are adjusted for the first, second and third gears;

"Double-motor parallel drive mode":When a sudden acceleration is needed, the power demand reaches the highest. At this time, all the components that can output power all output power, and the speed ratio is adjusted through three clutches, so that the power transmission combination of 1st gear, 3rd gear, 1st+2nd gear and 2nd+3rd gear can be realized, and the power performance can be fully exerted.

Overview of two parallel driving modes (simplified version, for reference only)

The parallel mode of almost all hybrid systems is to maximize the power, and "Chery Kunpeng DHT Hybrid System" is no exception. Through the cooperation of three groups of "clutches", more power transmission combinations are realized.

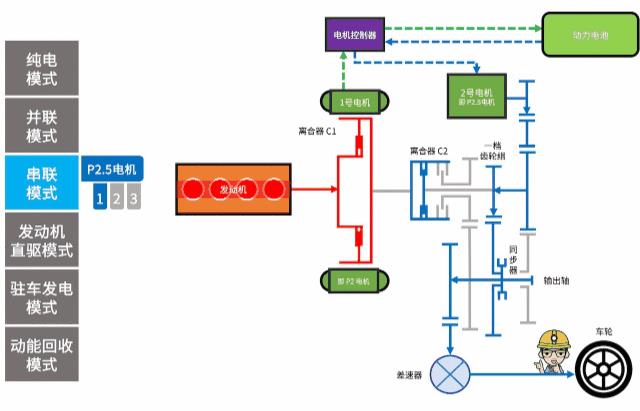

In-line mode (detailed version, for reference only)

Similar to the series mode logic of other DHT, the "engine" drives one "motor" (P2 motor) to generate electricity, while the other "motor" (P2.5 motor) drives the car. From the transmission path of power:

![http://www.wf2538.com.cn/wp-content/uploads/2024/03/92ITBVtK.jpg 3. Series connection (working principle of Kunpeng) [Simplified]. gif](http://www.wf2538.com.cn/wp-content/uploads/2024/03/92ITBVtK.jpg)

In-line mode (simplified version, for reference only)

1. "Engine" drives "P2 motor" through "clutch C1";

2. "P2 motor" charges "battery";

3. The "battery" discharges to supply power for the "P2.5 motor" used for driving.

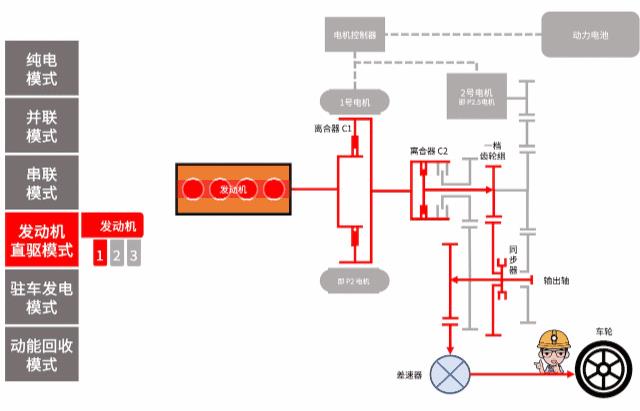

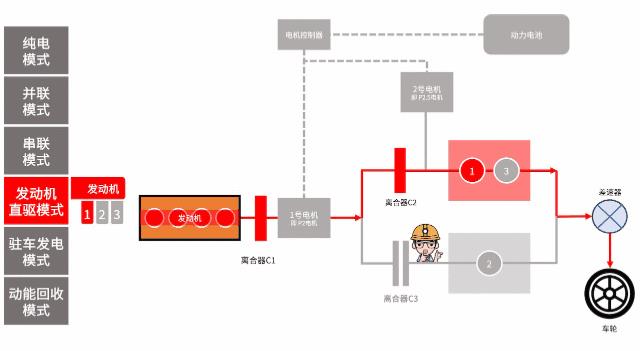

Engine direct drive mode (detailed version, for reference only)

The engine direct drive mode of "Chery Kunpeng DHT Hybrid System" is slightly different from other DHT logics, and it is mainly used when the "electric drive system" fails, such as the serious power loss of the "battery" or the failure of the "motor".

Engine direct drive mode (simplified version, for reference only)

Without the electric drive system, the logic of the work is the same as that of the traditional fuel vehicle, except that the general fuel vehicle uses a 6-speed or 7-speed powershift, and the "DHT" has only three gears, which greatly reduces the fuel economy. Therefore, the engine direct drive mode of "Chery Kunpeng DHT Hybrid System" should not be often used as a fault standby mode.

Parking power generation mode (detailed version, for reference only)

Similar to the parking power generation mode of BYD DM-i hybrid system, the clutch C1 is coupled, and the engine drives the P2 motor to charge the battery.

Parking power generation mode (simplified version, for reference only)

At present, I haven’t tested the car equipped with "Chery Kunpeng DHT Hybrid System", and I don’t know if it is the same as BYD’s calibration or use logic. For example, it needs to be put in P gear before it can be used; The opening and closing degree of throttle determines the charging power; And I am most concerned about whether I can set the charging power and charge automatically without stepping on the accelerator. (Did you say the voice of BYD car owners, and the comment area brushed a wave of "leg cramps")

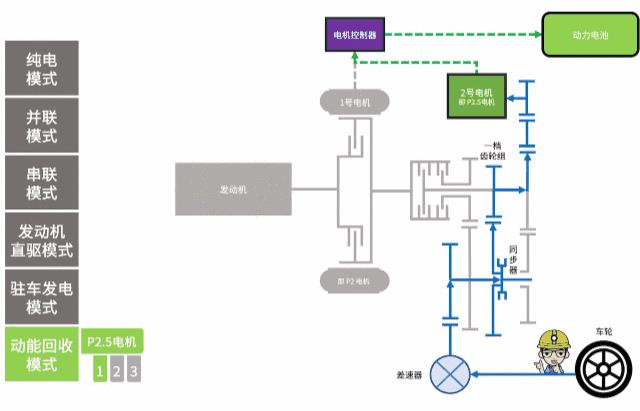

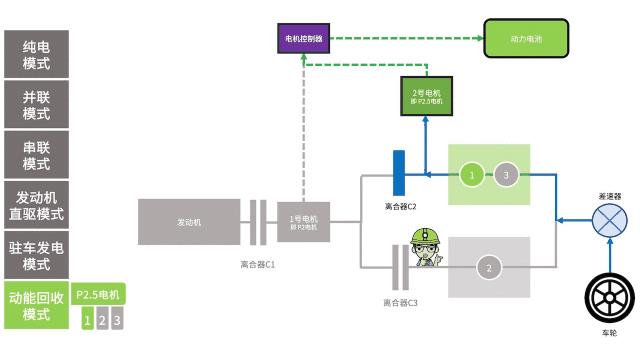

Kinetic energy recovery mode (detailed version, for reference only)

It can be regarded as the reverse power flow of "pure electric drive mode of P2.5 motor". When the vehicle slides or brakes, the kinetic energy of the whole transmission assembly is recovered by "P2.5 motor" and the battery is charged.

Kinetic energy recovery mode (simplified version, for reference only)

The kinetic energy recovery mode of "Chery Kunpeng DHT Hybrid System" is still quite interesting. After eliminating the unfavorable schemes of low transmission efficiency and long transmission path, the first gear and the third gear are still retained, and the kinetic energy recovery is achieved by using "variable gears" with different speed ratios.

Working principle list of Chery Kunpeng DHT hybrid system (for reference only)

If the above animation dazzles you, you can also clearly understand the "3 gears, 9 modes and 11 speeds" of "Chery Kunpeng DHT Hybrid System" through the above table. Of course, the above analysis of the structure and working principle of "Chery Kunpeng DHT Hybrid System" is only a personal understanding, for reference only. Welcome to comment in the comment area.

Schematic diagram of working principle of Chery Kunpeng DHT hybrid system (simplified version, for reference only)

From the structure of "Chery Kunpeng DHT Hybrid System", we can see the shadow of some traditional "powershift", and whether the layout of two "motors" reminds us of similar structures.

Audi A3 Sportback e-tron(2017), full of German and German P2 motor architecture.

For example, the positioning of "P2 motor" that can be driven and generate electricity reminds me of the "P2 motor architecture" full of virtue and flavor.

Do you remember whose P2.5 motor architecture this is?

Another example is adding "P2.5 motor" to "powershift", which reminds me of the "P2.5 motor architecture" used to drive 2nd gear, 4th gear, 6th gear and reverse gear.

Schematic diagram of Chery Kunpeng DHT hybrid system

However, "Chery Kunpeng DHT Hybrid System" combines "double clutch" technology with "P2 motor architecture" and "P2.5 motor architecture", which is not a flattering and easy technology tree. It can be seen only from the number of components of the whole set of "DHT" (1 engine, 2 motors, 2 sets of ". Obviously, when choosing the hybrid technology, Chery Automobile once again embodies the characteristics of its "engineering straight man"-the dead hacking technology. I can only say that it is "unexpected and reasonable".

Schematic diagram of Chery Kunpeng DHT hybrid system

For consumers, they don’t care about the technical difficulty of a hybrid system, but pay more attention to the driving experience. I believe that the "3-speed, 9-mode and 11-speed" of the "Chery Kunpeng DHT Hybrid System" can give full play to its technical advantages. At present, the mass-produced models have been listed, so let’s leave it to time.

At present, the listed model equipped with "Chery Kunpeng DHT Hybrid System" is "Tiggo 8 PLUS Kunpeng e+". According to the official data of Chery Automobile:

Tiggo 8 PLUS Kunpeng e+

The powertrain of the "Tiggo 8 PLUS Kunpeng e+" two-wheel drive version consists of a "1.5T hybrid engine" and "Kunpeng DHT". The output power of the "engine" is 115kW, the maximum output power of the system is 240kW, the maximum output torque is 565N·m, the acceleration time from 0 to 100km/h is 7 seconds, and the NEDC battery life is 100 km.

Tiggo 8 PLUS Kunpeng e+ 1.5T DHT Style E+(165,800 in 2022)

In mid-January, 2022, Chery Automobile announced that the prices of two versions of "Tiggo 8 PLUS Kunpeng e+" were 151,800 yuan and 165,800 yuan respectively (after subsidies). Later, a four-wheel drive version of "P4 Motor" was added. The maximum output power of the system can reach 341kW, and the 0-100km/h acceleration time of the four-wheel drive model is 4.9 seconds.

Parameters of Chery Kunpeng DHT hybrid system (for reference only)

Schematic diagram of working principle of Chery Kunpeng DHT hybrid system (detailed version, for reference only)

You can see that all the "Chery Kunpeng DHT Hybrid System", "Great Wall Lemon Hybrid DHT System" and "Lei Shenqing Hi·X Hybrid System" have started to adopt multi-gear DHT structure (although there are technical differences), and their basic logic is to improve the efficiency of the whole powertrain, while "Chery Kunpeng DHT Hybrid System" is a classic multi-gear DHT structure. Therefore, I hope you can save the above picture (2 weeks after liver transplantation) for future reference. Of course, the pictures are free of charge in Bai Piao, so why not pay attention and praise? !

Tiggo 8 PLUS Kunpeng e+

Finally, as far as the current progress of the "new four modernizations" in the automobile industry is concerned, Chery Automobile is not the fastest. However, in February this year, Luxshare, the giant of Apple’s electronic industry chain, announced that it would form a joint venture company with Chery New Energy, specializing in the R&D and manufacturing of new energy vehicles, providing cutting-edge R&D and design, mass production platform and seaport for Chery’s core parts business, and striving to realize the company’s long-term goal of becoming a leading manufacturer of automobile parts Tier 1. I believe that in the next time, we will see more actions of Chery Automobile.